Choosing between manual-assisted and auto stretch wrapping machine

Choosing between manual-assisted and auto stretch wrapping machine

Blog Article

Enhance Your Packaging Process With a Trustworthy stretch wrapping machine for Ideal Efficiency

In the complicated globe of logistics, a reliable product packaging process is an important variable that can dramatically influence a business's bottom line. The unification of a reliable stretch wrapping machine not only enhances performance yet likewise makes sure the integrity of goods throughout transit. This piece of machinery might be the secret to opening improved efficiency, waste reduction, and substantial expense financial savings. Interesting, isn't it? Allow's explore better.

Understanding the Role of a stretch wrapping machine in Product Packaging

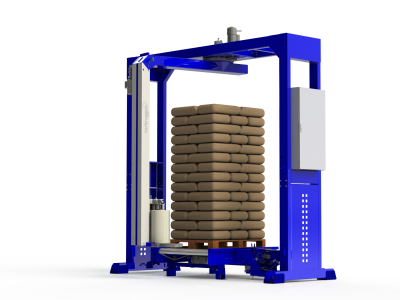

Making certain item safety throughout transit, a stretch wrapping machine stands as an essential possession in the packaging market. Its main function focuses on enveloping products in a protective layer of film, therefore preserving item stability and minimizing damage threats throughout transport.

The machine's procedure is complex yet effective. Item are placed on a rotating base while the movie is untangled from a set roll. As the turntable rotates, the film is applied evenly over the objects, ensuring complete coverage.

This maker's relevance prolongs beyond plain wrapping. stretch wrapping machine. It enhances the piling security of products, minimizing the likelihood of crashes. Even more, it safeguards things from dirt, wetness, and other ecological variables, maintaining their high quality up until they get to the consumer

Fundamentally, a stretch wrapping machine is an essential device for companies seeking to enhance their packaging procedure, secure their products, and streamline their logistics procedures. Its duty is indispensable to the effective and effective functioning of the modern-day product packaging industry.

When Choosing a stretch wrapping machine, key Features to Consider.

When picking a stretch wrapping machine for product packaging objectives, numerous vital features require consideration. These include reviewing the machine's efficiency, understanding its load capability, and assessing its resilience and maintenance requirements. An educated choice rest on a comprehensive evaluation of these variables.

Although efficiency might not be the first thing you think about when thinking about stretch wrapping devices, it is an important variable that can considerably influence your packaging procedure. An effective machine can dramatically minimize waste, lower prices, and improve productivity. When examining efficiency, consider the maker's rate. A faster machine can wrap extra bundles in much less time, enhancing your procedure's result. Check for programmable setups, which can tailor the covering procedure to suit different items, minimizing unnecessary use of materials. Furthermore, an effective equipment should call for marginal maintenance, making certain continual operation without frequent interruptions. The device's power consumption is another essential variable, as a maker that utilizes much less power can cut running costs. Keep in mind, a reliable machine assurances optimum performance.

The Influence of a Trustworthy stretch wrapping machine on Productivity Levels

Buying a trusted stretch wrapping machine can significantly boost performance degrees in a packaging operation. These machines automate the covering process, permitting consistent and reliable performance that outmatches hand-operated covering techniques.

A dependable device reduces downtime triggered by mechanical failings or upkeep requirements. This guarantees a consistent flow of work, preventing delays and stockpile in the production chain. High-grade stretch wrapping machines also have flexible settings for different product types. This versatility permits organizations to manage a wide series of things without taxing hand-operated modifications.

In addition, these devices call for less human intervention, liberating employees to concentrate on other necessary tasks. This optimization of human resources can bring about a boost in overall operational productivity.

In significance, a dependable stretch wrapping machine is an important financial investment that can improve productivity levels in try this out a packaging procedure, giving substantial benefits in effectiveness, adaptability, and resource utilisation.

Ways in Which a stretch wrapping machine Minimizes Waste

A stretch wrapping machine's function in waste reduction is substantial and multifaceted (stretch wrapping machine). Not only does it lessen product use by successfully covering items, yet it additionally safeguards goods from damage during handling and transport. This double benefit lead to notable expense financial savings and advertises sustainability in the packaging process

Minimizing Material Usage

Expense and Time Cost Savings: The Financial Advantages of a stretch wrapping machine

In addition, the equipment's regular wrapping technique decreases item damage, lowering replacement costs and boosting customer satisfaction. Using a stretch wrapping machine also causes an extra foreseeable budgeting process, as the quantity of stretch film utilized per pallet corresponds, unlike hands-on covering which can differ significantly.

Inevitably, the cumulative financial savings in labor, products, and potential product loss make the preliminary financial investment beneficial. In the lengthy term, services can accomplish significant financial benefits by integrating a stretch wrapping machine into their product packaging procedure.

Conclusion

Although efficiency could not be the initial thing you believe of when considering stretch wrapping makers, it is an essential aspect that can dramatically influence your product packaging procedure. The device's energy intake is an additional essential factor, as a maker that uses less power can reduce operating expenses. In addition, a device supported by a thorough warranty and exceptional consumer service can minimize possible troubles in maintaining the device's ideal efficiency.To understand the ways in which a stretch wrapping machine minimizes waste, one have to first think about the cutting-edge style of these machines. In this way, stretch wrapping equipments not just enhance the YOURURL.com high quality of product packaging yet also promote a much more efficient and environmentally-friendly process, showing their important function in modern-day packaging operations.

Report this page